Australian clean energy company MGA Thermal has unveiled the first stage of its new manufacturing facility in Port Stephens.

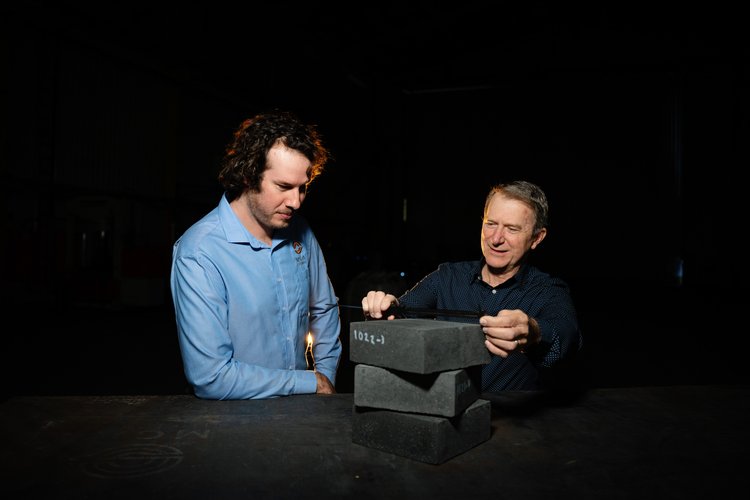

MGA Thermal manufacture blocks which consist of a purpose-invented material called Miscibility Gap Alloy (MGA). The blocks are made of that matrix material which keeps the block solid and a metallic material is dispersed as particles. The matrix is highly conductive and rapidly distributes heat, keeping the particles in place as they melt when heat energy is absorbed.

The blocks store thermal energy which is released as they cool.

The company describes the process as being akin to a chocolate chip muffin. Essentially, when you heat the muffin the chocolate chips melt but the cake itself stays solid. The chocolate chips absorb the energy from the oven melting, but they stay in place because of the cake. As the cake cools the the liquid chocolate releases its absorbed energy, it returns to be a chocolate chip. The process can be repeated over and over.

The manufacturing facility at Tomago will be capable of manufacturing more than 1,000 blocks, or 1MWh of energy storage, per day by the end of 2022.

The initial run of blocks will be used to kick off MGA Thermal’s partnership with the Toshiba International Corporation and Graphite Energy to produce low-cost green hydrogen thanks to a $9.8 million grant from the Australian Government’s Modern Manufacturing Initiative.

“If current market sentiment and the impacts of climate change are telling us anything, it’s that we can no longer hold off on the renewable energy transition. While conventional storage technologies like batteries are no doubt important to that mission, we believe our MGA Thermal Blocks will be a major part of that transition, to retrofit existing thermal power plants and support development of low-cost renewable energy storage and green hydrogen,” said Erich Kisi, co-founder and CEO of MGA Thermal.

“Utilities around the world have told us they need this type of technology to make that move, and we are well on our way to building the capacity to meet that demand.”

Image: MGA Thermal website